Manual Positioning Tables for Testing Aircraft Instruments

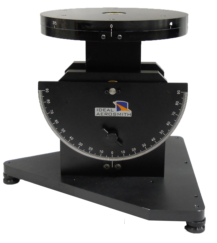

Model 1300: The 1300 series Manual Tilt & Turn Tables from Ideal Aerosmith are designed for precision calibration of gyroscopic instruments or any devices requiring a tilt input in one or two axes. The table provides a portable, stable and precise positioning platform with lasting durability.

- Small and lightweight for easy benchmounting and manual operation

- Two degrees of freedom for tilting and rotating test instruments

- Knurled mounting screws on the table top

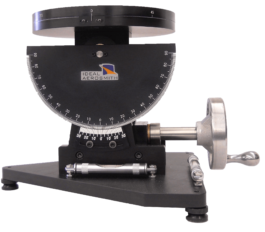

Model 1310: The 1310 series Manual Tilt & Turn Tables are designed for precision calibration of gyroscopic instruments or any devices requiring a tilt input in one or two axes. The table provides a portable, stable, and precise positioning platform with lasting durability.

- Small and lightweight for easy bench mounting and manual operation

- Two degrees of freedom for tilting and rotating test instruments

Model 1501: The Model 1501 Test Table is a single-axis manual positioning table used to provide positioning indexes for inertial guidance systems for the purposes of calibration and acceptance testing. The table is moved by hand to the desired position and a shot pin is engaged to hold the table’s position.

- Manually-operated horizontal tilt and azimuth axis

- Position Accuracy: ± 6 arc minutes

- Position Repeatability: ± 30 arc sec

- 32-inch table top

Model 1503-24-EN: The Model 1503-24-EN Three-Axis Manual Positioning Table is designed to provide precise position feedback via the optical encoder for the development and/or production testing of navigation sensor systems such as tilt sensors and turn and bank indicators.

- Manually operated

- Optical encoders for precise feedback

- Position Accuracy: ±1 arc minute

- Position Repeatability: ± 30 arc sec

Model 1502B-32: The Model 1502B-32 Manual Positioning Table is designed to provide precise position for the development and/or production testing of navigation sensor systems. The 1502B-32 system may be integrated with a customer developed test station.

- Manually-operated horizontal tilt and azimuth axis

- Position Accuracy: ± 6 arc minutes

- Position Repeatability: ± 30 arc sec

Model 1501T: Ideal Aerosmith’s Model 1501T is a single-axis manual tilt table. Designed for testing an IMU (Inertial Measurement Unit), this system supports the IMU on the upper mounting surface and additional electronics on the lower mounting surface with minimal counterweights.

- Manually operated horizontal tilt axis

- Position Accuracy: ± 10 Arc-Sec

- Position Repeatability: ± 5 Arc-Sec

- 35 line user signal

Scorsby Motion Tables

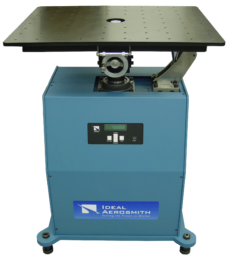

Model 1421: The Model 1421 Scorsby Motion Test Table is designed to simulate the roll, pitch, and yaw motions of an aircraft during flight. Primarily used for shop, production, qualification testing, and exercising of gyroscopic aircraft instruments, the Ideal Aerosmith Scorsby table is a standard in the aircraft industry.

- Variable speed from 1 to 10 Cycles/Minute

- RS-232 Interface

- Automatic homing

- Easy-to-adjust tilting head with engraved markings

- Easy-to-adjust tilting head with engraved markings

- Positive stop allows quick setting of the tilt head to frequently used positions

- Motor and drive train designed for reliability and long life

Model 9790-BVR: The Model 9790-BVR Scorsby Motion Test Table from Ideal Aerosmith is designed to simulate the three motions of flight: roll, pitch and yaw. Originally designed for shop, production, qualification testing and exercising of gyroscopic aircraft instruments, the Scorsby table became a standard in the aircraft industry.

- Heavy-duty table frame designed for heavy load capabilities

- Approved for many aircraft gyroscopic instrument tests

- Anodized aluminum mounting platform for durability and corrosion resistance

- Designed with ball bearings for smooth motion and long life

- Flat, precision-ground table top mounting surface

Tachometer Testers

Model 1921: The Model 1921 Tachometer Tester is used for the testing and calibration of electrical and mechanical tachometer generators and indicators, specifically handheld models. Two variable speed brushless motors eliminate the need for gears while providing for a testing range of 10 to 50,000 RPM.

- 10-50,000 RPM Actual Drive Speed

- High accuracy

- 0.01 Display Resolution

- Direct Drive

- Bi-directional

Model 1790: This test instrument is used for testing and calibration of electrical and mechanical tachometer generators and indicators. A high quality DC motor is coupled directly to a 1/4 inch square hole drive (AN Pad). This tachometer tester output can be converted to a wide variety of adapters and different tachometer interfaces.

- 250-10,000 RPM Tachometer Testing Range

- 250-5,000 RPM Actual Drive Speed

- Maximum Torque: 60 oz-in

Non-Magnetic Rate And Positioning Tables

Model 2203-TH-NM: Trip Guardian™ 2203-TH-NM Automated Three-Axis, Non-Magnetic Positioning Table System is intended for use in calibration and verification of MWD downhole directional instruments, including magnetometers, gyroscopes, and accelerometers.

- Limited rotation on all three axes

- ±30 arc second position accuracy

- Thermal chamber and controller

- AERO 3500 Commander controller

- Air amplifier for cooling the DUT

- Temperature range ambient to 225°C

Model 1503-TSNM-A: The 1503-TSNM-A Series test table is a three-axis, nonmagnetic manual positioning table. This table can be used for the calibration of downhole directional instruments including magnetometers, gyroscopes, and accelerometers. The tables are constructed of aluminum, brass, and phenolic.

- Payloads up to 4 inches in diameter and 54 inches in length

- Temperature Range: Ambient to 175°C or 210°C

- Air Amplifier Kit for faster cooling of UUT and chamber

- 210°C High Temperature Option

Model 1503-TS-SPL: The Model 1503-TS-SPL test table is a three-axis non-magnetic manual positioning table. This table can be used for testing magnetometers, gyroscopes and accelerometers as well as complete down-hole directional instruments. Table is uses “Total Field Calibration” method.

- Heating Capacity: 1800 watts

- Temperature Range: Ambient to 392°F (200°C)

- Table Test Load Capacity: 50 lbs. centered

- Overall Table Dimensions: 30.5W x 82.9D x 58.9H inches

- Various mounting kits

Centrifuges

Model 1068-2: 1068-2 is designed to apply a large centrifugal force to a payload. Acentrifuge is typically required for applications with larger payloads, and/or higher G requirements. The 1068-2 tests from 0 to 1000 G’s at a 10.5-inch (267 mm) radius. Payload capacity is a 24 inch cube at an 8 inch height at 50 lbs.

- Range 0-250 G’s at a 25-inch radius

- Maximum G-Lbs 20000 G-lbs

- Rate Range 0-600 RPM

- Slip Rings 108 lines at 3A

Model 1221: The 1221 is designed to apply a large centrifugal force to a payload. A centrifuge is typically required for applications with larger payloads, and/or higher G requirements. The 1221 tests from 0 to 250 G’s at a 25-inch radius. Payload capacity is an 18 inch cube (457 mm) at 200 lbs. (91 Kg) per arm.

- G-Range 0 to 250 G’s at a 25-inch radius

- Maximum G-lbs 20000 G-lbs

- Payload Capacity 18 inch cube, (457 mm); 200 lbs.

Model 1068-1: The 1068-1 is designed to apply a large centrifugal force to a payload. A centrifuge is typically required for applications with larger payloads, and/or higher G requirements. The 1068-1 tests from 0 to 100 G’s at a 22-inch (559 mm) radius. Payload capacity is a 12 inch cube (305 mm) at 50 lbs.

- G-Range 0 to 100 G’s at 22-inch (559 mm) radius

- Maximum G-lbs 5000 G-lbs

- Rate Range 0-400 RPM