Connected Field Service

ICONICS CFSWorX™ is a solution designed to streamline the efficiency of field service organizations through intelligent scheduling and reliable notifications. It empowers field service workers and maintenance personnel to move past the legacy break/fix model towards more proactive facilities and equipment management.

Key Features

Smart App for Connected Field Service Workers

Automatically Assigns Tasks Based on Location, Schedule, Availability, and Skill Level

Intelligent Scheduling with Reliable Notifications

Workflow-based Escalation for Critical Issues

Integrates with Microsoft Dynamics 365 and Other Popular ERP/CRM Systems

Comprehensive Audit Trail for Reporting and Accountability

BridgeWorX64

The BridgeWorX™64 service provides the latest 64-bit data bridging technology for ICONICS products. Graphical data bridging enables users to rapidly implement data orchestration and integration tasks that adhere to business logic without requiring programming. BridgeWorX64 can access Microsoft SQL Server, Oracle, Microsoft Access, SAP, and virtually any real-time or archived manufacturing or business data source.

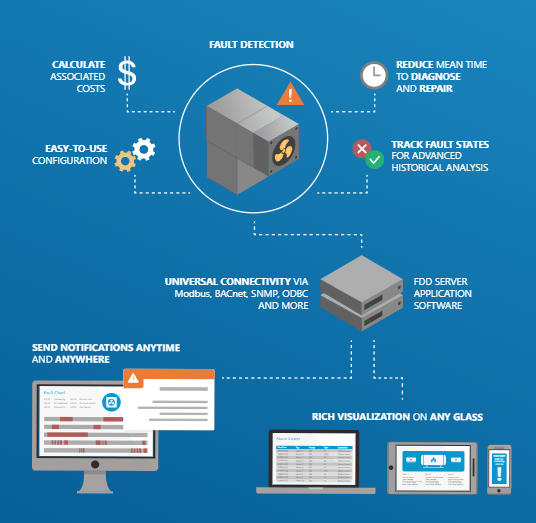

Fault Detection and Diagnosis

Fault Detection and Diagnostics (FDD) technology significantly reduces costs and improves operational efficiency. It incorporates a standard library of fault rules that can be customized to predict equipment failures and advise personnel of preventive actions.

Benefits of ICONICS FDD Solutions

Predict, Reduce and Eliminate Equipment Downtime

Automatically Detect Faults and Receive Real-time Notifications

Utilize Preconfigured Fault Rules in the Standard Rules Library

Reduce Maintenance and Determine Probable Causes

Rich Visualization and Reporting

Return on Investment Typically Within 12 to 18 Months

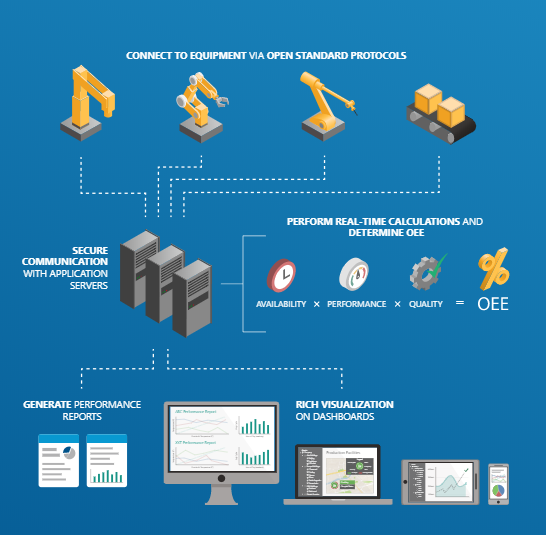

Overall Equipment Effectiveness

OEE software provides a full end-to-end process performance monitoring solution that provides actionable intelligence to users at any level of an enterprise. Highly accurate, real-time and historical information can then drive global operational efficiency and help to gain a competitive advantage. OEE software solutions typically involve pre-built calculations, downtime analytics, and production scheduling; all of which combine to help ensure effective business processes.

Benefits

Advanced Analytics and Automated Reporting

Prioritize Workloads

Accountability

Preconfigured Templates

Connectivity to Multiple Data Sources

Powerful Data Mining Tracks Real-Time KPIs

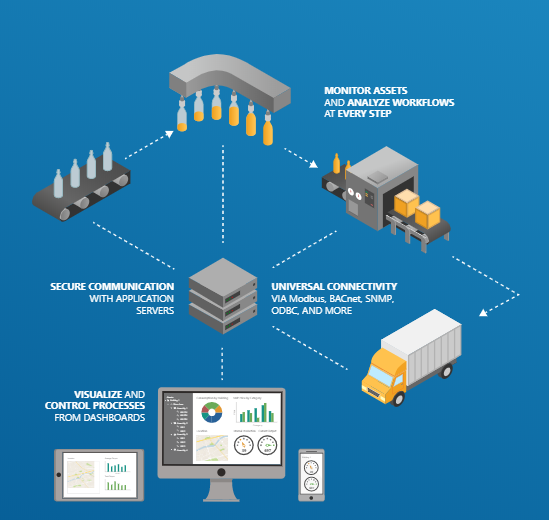

Manufacturing Execution Systems (MES)

Most modern plants use a Manufacturing Execution System (MES) to manage and monitor work in progress on the factory floor. MES solutions involve system control systems that rely on up-to-date info to provide a snapshot of the current state of products being manufactured. In regulated industries, it is also the repository for critical lot and process data.

Benefits

Fast, Intuitive Graphical Workflow Designer

Data Mine Any Real-Time Data Source

Powerful Transaction Workflow Scheduler

Seamlessly Orchestrate Historical Data Integration

Centralized Unified Data Manager

Real-Time OPC Compliance