Switches for Pressure, Flow, Level and Temperature

Flow Switches

Model V9F: These specifically engineered units are for use in tight spaces where outlet flow is directed at 90° relative to the inlet. Not using an elbow results in a reduction of plumbing and weight as compared to an inline design.

- Orthogonal inlet and outlet

- Space and weight saving

- Magnetic operation

- Hermetically sealed switch

Model V121F: For high flow switching applications up to 20 GPM, this design offers the same proven advantages of the V121F series but features larger fittings for reduced pressure drop. The inline design is easily integrated into most plumbing layouts.

- Nonmagnetic operation

- Pressure and attitude immunity

- Compatible with “dirty” media

- Inline mounting

Model V22F: The 10 GPM range of V22F covers most common flow ranges in aerospace and military applications. The nonmagnetic design eliminates concerns about interface from external magnetic fields.

- Nonmagnetic operation

- Higher flow applications

- Pressure and attitude immunity

- Inline mounting

- hermetic seal

Pressure Switches

Gauge Pressure Switches

Model XP: The XP Series Transducers are designed for demanding aerospace applications that include the monitoring or control of flight surfaces, braking, thrust reversers and also landing gear actuators. These use Polysilicon sensor technology.

- RTCA DO-160 Qualified

- 5 Million Cycle Life

- Stainless Steel Construction

- No Internal Seals increases reliability

Model PV56M: The PV56M is a modular design for low-vacuum settings that require small actuation values. This polyimide diaphragm sensor provides long cycle life and high temperature capability for vacuum applications like plenum vacuum.

- Double polyimide diaphragm

- The design is small yet very Sensitive

- Environmentally sealed

Model P20M: The P20M features an incredibly low pressure setting range despite its small size. The polyimide diaphragm sensor provides both long life and media resistance for many liquid and gas applications.

- Negative-rate belleville spring design

- Longer life, accuracy and repeatability

- Media resistant

Differential Pressure Switches

Model DA128S: For pressure settings as low as 1.0″ H2O, this product features a large sensing area for exceptional sensitivity and accuracy. Uses include critical air flow, filter and compartment Delta-P applications.

- Settings down to 1.0″

- ± 0.1″ accuracy of low pressure

- No age-controlled elastomers

Model D45C: The 0.1 PSI accuracy of this low pressure product is accomplished by use of a welded Ni-Span-C pressure sensing capsule. This material has a “constant modulus” which provides excellent accuracy over temperature.

- Small size – 1.63 Dia. x 2.5″

- ± 0.1 PSI repeatability

- No age control elastomers

Model D16M: This small product, for pressure settings up to 75 PSI is designed specifically for applications where one or both of the media are liquid media. Pressure is sensed by a laminated polymide diaphragm.

- Small size, 0.25 lbs tipical weight.

- Plug-in interface

- Hermetically sealed

- Compound snap-action

Altitude (Absolute) Pressure Switches

Model A45C: The A45C is our most sensitive skeletal (no pressure fitting) altitude switch for use with air or inert gas. This unit features a Ni-Span-C capsule for superior setpoint stability over a wide range of temperatures.

- Ni-Span-C capsule reduces setpoint shifts caused by temperature changes

- Easy install – no plumbing to hook up

Model E37C: The E37C is our smallest and lightest remote sensing altitude switch for use with air or inert gas. The capsule and electrical switch are encased in an environmentally sealed chamber for protection from severe elements.

- Remote monitoring

- Environmentally sealed

- Ni-Span-C capsule reduces setpoint shifts caused by temperature changes

Model A37C: The A37C is our smallest and lightest skeletal (no pressure fitting) altitude switch. It features a Ni-Span-C capsule for superior set point stability over a wide range of temperatures. Three standard mounting options are available.

- Ni-Span-C capsule reduces setpoint shifts caused by temperature changes

- Easy install – no plumbing to hook up

Liquid Level Switches

Model L14F: The L14F is the solution to many liquid level applications. With lengths up to 12″ and top or bottom mounting options, these units can be configured to switch at various rising or falling level locations relative to the mounting surface.

- Top or bottom mount

- High pressure capability

- Multiple switching positions

- Hermetically sealed switch contacts

Model L16H: The counterbalanced float of the L16H is used in side mount applications requiring critical stability and sensitivity. The solid float is able to withstand high pressures (up to 5000 PSIG) and the materials used in construction are immune to most fuels and oils.

- High pressure immunity

- Compatible with most fluids

- Hermetically sealed electrical switch

- Sensitive, counterbalanced float

Temperature Switches

Model T8B: Precision Sensors line of temperature switches has been designed to maximize isolation of the element and the probe from the mounting fitting and shell. This results in faster response and the least possible conductivity error.

- Fast response time

- Low conductivity loss

- Up to 30g vibration resistance

- Burst pressure to 7,500 PSI

Model TS12T: Precision Sensors line of RTD temperature probes has been designed to maximize isolation of the element and the probe from the mounting fitting and shell. This results in faster response.

- Fast response time

- Low conductivity loss

- Burst pressure to 12,500 PSI

- Special coefficients available

Sensors and Transducers

Pressure Transducers

XP Series: Designed for demanding aerospace applications that include the monitoring or control of flight surfaces, braking, thrust reversers and landing gear actuators. No internal seals to degrade or cause leakage, the flameproof stainless steel welded design eliminates installation effects

- Pressure range 0-5000 PSIG

- RTCA DO-160 Qualified

- 5 Million Cycle Life

- Works with all Hydraulic Fluids

Model 7100 Flight Heritage Low Level Pressure Transducer: Provides high-accuracy measurements of up to ±0.1% FSO. Its flight heritage, lightweight design & higher shock and vibration levels ideal for use within demanding aerospace and defense applications

- High accuracies upto ±0.1% FSO

- Temp -65 °F to +250 °F(-54 °C to +121 °C)

- MIL-STD-810F shock and vibration specification

Model 7200 Flight Heritage Pressure Transducer: High-accuracy pressure measurements within commercial aviation, military, aerospace, UAV, satellite, and defense applications. This highly rugged pressure transducer is designed to meet both MIL-STD-461 and MIL-STD-810G

- Up to ±0.1% FSO accuracy (RSS)

- Optional 10X proof pressure

- 0 to 1 thru 0 to 15K PSI (69 MBAR to 1,034 BAR)

- Full NIST traceability

- Designed to meet *MIL-STD-810F

Model 7202 Flight heritage pressure transducer: Smallest and lightweight aerospace designs that GP:50 offers. It provides very high accuracy and improved thermal performance and is manufactured and tested to meet MIL-STD-461E and MIL-STD-810F.

• Compact and lightweight design

• ±0.10% static accuracy option

• Temperature output options

• Ranges up to 0-15K PSIA

Model 8200 Flight Heritage Digitally Corrected Pressure Transducer: Flight heritage, high level pressure transducer. Digitally corrected to provide high-accuracy pressure measurements with a proprietary sensor design for added zero stability for commercial & defense applications.

• High accuracy, up to 0.05% available

• 10X overload option

• 0 to 5 Vdc, or 0 to 10 Vdc or 4-20mA output

• 4 wire Isolated output option

Model 7300 Flight Heritage Differential Pressure Transducer: flight heritage, differential pressure transducer digitally corrected to provide high-accuracy pressure measurement. The compact, proprietary sensor design provides added zero stability for commercial & defense applications.

• Digital correction provides an optional 0.05% FSO accuracy

• Extremely lightweight, <8 oz (0.2 kg)

• 0 to 5 Vdc, 0 to 10 Vdc, or 4-20mA output

• Line pressure shift <1% FSO/1000 PSI

• Ranges from 0-1 thru 0-500 PSID

Model 8300 | Flight Heritage Digitally Corrected Differential Pressure Transducer: flight heritage, differential pressure transducer, providing high reliability with high accuracy. The compact, proprietary sensor design provides years of reliable measurement

• Accuracy option to 0.05% FSO

• Lightweight, <8 oz (0.2 kg)

• 0 to 5 Vdc or 4-20mA output

• 1000 PSI line pressure rating

• Ranges from 0-1 thru 0-500 PSID.

Model 7201 | Flight / Spaceflight Heritage High-Accuracy Pressure Transducer: High-accuracy, low-noise, flight-heritage pressure transducer, designed to provide high-reliability within demanding aerospace environments. Durability and performance of this transducer across hundreds of applications.

• Space flight qualified per MSFC-HDBK-527

• Radiation hardened to 40 KRAD

• Measurement accuracy to <±0.3% FSO (RSS)

• 0-5 Vdc output

• Designed to meet 7-year LEO requirements

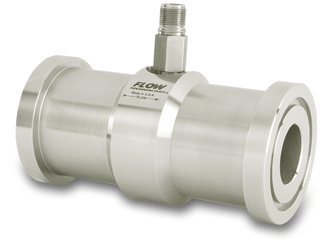

Model 7900 Flight Heritage Flow-Thru Pressure Transducer: Light weight flow-thru pressure transmitter designed for flight propulsion systems. The flow thru design is engineered to measure up to 0.1% of full scale pressure flow across the sensor and will stand up to the rigorous conditions associated with propulsion applications.

• Lightweight, compact size <55 grams

• Flight qualified

• High accuracy, <0.1% FSO RSS

• “S” Class electronics available

• Full traceability

Model 7901 Space Heritage Flow-Thru Pressure Transducer: Light weight unit designed for flight propulsion systems. Engineered to measure up to 0.1% of full scale pressure across the sensor and will stand up to the rigorous conditions associated with space propulsion

- Lightweight, compact size <55 grams

- Flight qualified

- High accuracy, up to <±0.1% FSO RSS

- Full traceability

- Rad-hard 100 KRAD optional

Model 7720 Cryogenic Pressure Transducer: Measurement accuracy in temperatures as low as -320 °F (-196 °C). Lightweight, all stainless steel construction with choice of either 4-20 mA, 0 to 5 Vdc, or 0 to 10 Vdc output; or optional digital protocols.

- Reliable cryogenic performance to -320 °F (-196 °C)

- Hydrogen and LOX compatible

- Isolated remote electronics via stainless steel armored flex tubing

- Standard accuracy to +0.3% FSO

Model 7730 Dual Cryogenic Pressure Temperature Transducer: provides pressure and temperature measurement in one device down to -320 °F (-196 °C). The remote mounted electronics offers a high level output of 4-20 mA, 0 to 5 Vdc or various digital protocols at high accuracy. 100 or 1,000 Ω platinum RTD is available as well as dual analog outputs.

- Cryogenic service down to -320 °F (-196 °C)

- Isolated electronics provide 4-20 mA, 0-5 Vdc or digital outputs

- Remote electronics via stainless steel armored cable

- High accuracy, 0.3% RSS standard (0.1% available)

Model 7780 High Temperature Pressure Transducer: Measurement accuracy in temperatures up to +350 °F (+177 °C). The Series features a lightweight, all stainless steel construction with choice of either 4-20 mA, 0 to 5 Vdc, or 0 to 10 Vdc output; or optional digital protocols.

- Process temperature rated to +350 °F (+177 °C)

- Onboard remote electronics via stainless steel armored flex cable

- Standard accuracy to +0.3% RSS (Optional +0.1%

- Hydrogen and LOX compatibility

Model 7790 High Temperature – Pressure & Temperature Transducer: Provides pressure and temperature measurement up to +350 °F (+177 °C). The remote electronics provides a high level output of 4-20 mA or 0 to 5 Vdc while reducing the overall footprint by integrating pressure and temperature measurement in one device.

- +70 °F to +350 °F (+20 °C to +177 °C) Process temperature

- High accuracy temperature output to ±1% FSO

- High accuracy pressure output to ±0.1% FSO

- Hydrogen and LOX compatibility

Model 7500 Subsea Pressure Level Transducer: designed to provide accurate measurements to 30,000 FT seawater. Its highly corrosion-resistant design meets the tough environmental challenges of offshore oil and gas, naval and ROV applications. Designed to meet stringent MIL-spec standards.

- Depth rated to 30K ft WC (9,144 meters)

- Pressure ranges up to 20K PSI (1,379 BAR)

- High accuracy 0.3% RSS (0.1% RSS available)

- Compact, sea water rated design

- 316L, Inconel and Hastelloy material options

Model 7540 Subsea Marine Service Differential Pressure Transducer: Highly rugged differential pressure transducer, designed to address the tough environmental challenges of subsea and other marine service environments. It is designed to meet stringent MIL and MIL-spec standards for high-reliability within extreme environments.

- Ranges from 30 thru 7,500 PSID (2 thru 517 BAR)

- Upto 10K PSI (689 BAR) line and proof pressure

- Depths to 30K ft WC (9,144 meters)

- NIST traceable

Model 7450 High Line – Low Range Aerospace Differential Pressure Transducer: High accuracy aerospace grade transducer, available with static line pressure to 5,000 PSI. Differential ranges as low as 0-2.5” WCD and a 500 PSI proof pressure are standard on all ranges. A custom subsea rated design allows operation to 23,000 FT SW.

- Ranges of 2.5” WCD thru 100 PSID (6.9 BAR)

- Upto 5,000 PSI line pressure option (345 BAR)

- ±0.1% FSO accuracy

- True Wet-Wet design

Model 7400 High Line Aerospace Differential Pressure Transducer: High-pressure, aerospace grade differential pressure transducer. Stainless steel design allows it to effectively measure both corrosive fluid and industrial gas pressures to high degrees of accuracy and repeatability. Its optional 10X proof pressure and 10K PSI (689 BAR) line rating also facilitates its use within demanding aircraft engine and hydraulic systems

- High-accuracy to ±0.3% FSO

- Designed to meet MIL-STD-810F

- J-001/NASA 8739.3 workmanship

Model 241/341 High Accuracy Pressure Transducer: Compact, corrosion-resistant, all-welded stainless steel design offers ease of installation within space constrained environments. Static accuracy is available to ±0.05% FSO, with a total thermal error of 0.20% FSO over the compensated temperature range.

- High accuracy to ±0.05% FSO

- High thermal stability +/-0.20% FSO/100 °F

- -40 to +250 °F compensation

- Compact, lightweight, all stainless steel design

- Less than 4 millisecond response time

Model 140/240/340 Compact Industrial Pressure Transducer: Compact, rugged design to meet the demands of hydraulic and pneumatic applications found in process automation, test stand, and OEM applications. High corrosion resistance in pressure ranges from 0-25” WC (69 Mbar) to 30K PSI (2068 bar).

- Rugged, all stainless, welded construction

- Ranges 0 to 1 PSI thru 0 to 30K PSI (69 Mbar to 2068 Bar)

- 4-20mA, Vdc or MV/V output

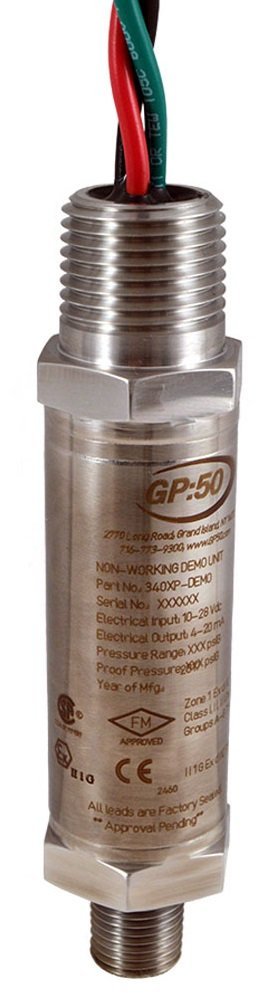

Model 240/340 AI/AN/AF| Hazardous Locations Pressure Transmitter: Rugged solution for hazardous approved areas, especially where space constraints are a concern. Its all welded stainless steel design will provide years of reliable service in some of the harshest environments.

- ATEX & IEC Approvals

- Improved accuracy and thermally compensated

- Ranges 0 to 1 PSI thru 0 to 50K PSI (69 Mbar to 3447 Bar)

- NACE MR-01-75 compliant

Model 142/242/342 Vehicle Test Pressure Transducer: Designed with aerospace criteria for industrial applications. The compact all-welded construction offers higher accuracy and a broad thermally compensated range.

- Ranges 0 to 50 thru 0 to 15K PSI

- Broad operating temperature range of -40 °F to +250 °F(-40 °C to +121 °C)

- Accurate up to ±0.1% FSO

- All-welded, hermetically sealed, stainless stee

Model 243/343 Dual Pressure and Temperature Transducer: Stainless steel, dual pressure and temperature transducer with 4-20 mA and 0-5 V output. Its compact design reduces I/O and insertion points where size and weight are considerations.

- Pressure and temperature in a single device

- Dual 4-20mA, 0 to 5 Vdc or RTD Temperature outputs

- Maximum process temperatures -65 °F to +250°F(-54 °C to +121 °C)

- Probe lengths from 3/4” to 7”

Model 540 CAN bus digital output pressure transducer: High resolution, accuracy, and improved thermal performance to meet the demands automotive, medical and laboratory test markets. CAN open protocol allows for multiple devices on a single bus reducing installation time and cost.

- CANbus SAE J1939 or CANopen protocol

- Ranges 0-1 PSI thru 0-10K PSI (3.5 thru 690 bar)

- Up to 0.05% FSO accuracy

- Field programmable options

Model 541 High Accuracy CANbus Transducer: Designed specifically for test stand applications, the CAN Bus protocol provides high resolution, reduced noise and improved thermal performance.

- CAN Bus protocol – J1939 or Can Open

- High accuracy ±0.05% FSO

- High thermal stability +/-0.25% FSO/100 °F

- -40 to +250 °F compensation

Model 741 High-Accuracy Digital Pressure Transducer: RS485 digital data transmission used in serial communication protocols standard for Industrial Control Networks and Data acquisition systems.

- Supports MODbus RTU and ASCII Protocols

- 4000 ft max data transmission

- EMI resistant

- High accuracy ±0.05% FSO

- Fast response time

Model 136/236/336 | Compact High-Accuracy Differential Pressure Transducer: Measures differential pressure ranges as low as 20” WCD and line pressures up to 1000 PSID (69 BAR) in a compact size.

- Upto ±0.05% FSO accuracy

- 1 PSID thru 500 PSID (0.1 thru 35 BAR D)

- Line pressure upto 1000 PSI (69 BAR)

- High shock and vibration resistance

Model 216/316 Low Range High Line Differential Pressure Transducer: Compact design which company’s own digital correction circuit technology for high accuracy and extended service life across a variety of applications.

- 2.5” WCD thru 200 PSID (14 BAR)

- Upto 5K PSI (345 BAR) line pressure options available

- Upto ±0.05% FSO accuracy

- Unidirectional and bidirectional outputs

Model 114/214/314 Ultra High Range Differential Pressure Transducer: offers +0.50% (BFSL) static accuracy over its standard ranges of 500 to 20K PSID (35 to 1,379 BAR D). Improved accuracy is available to +0.20%.

- Supports MODbus RTU and ASCII Protocols

- 4000 ft max data transmission

- EMI resistant

- High accuracy ±0.05% FSO

- Fast response time

Model 188/288/388 Miniature Flush Diaphragm Pressure Transducer: Unique design incorporates a specialty flush process connection. Allows transducer to effectively support higher viscosity fluid pressure measurements without port clogging or plugging.

- Rated for high shock and vibration applications

- -65 °F to +250 °F (-53.8 °C to +121.1 °C) operating temperature range (Optional -320 °F to +385 ºF)

Series 400-900 Digital Line of Pressure, Level, and Temperature Transmitters: Innovative pressure and temperature measurement options including USB, and SDI-12 transmitters as well other well-established digital protocols such as CAN bus and HART.

- 400 Series: HART Communication

- 500 Series: CANbus or CANopen

- 600 Series: USB output

- 700 Series: RS485 ASCII or Modbus output

- 800 Series: RS232

- 900 Series: SDI-12

Model 189 Miniature Static Pressure Transducer: Miniature design that provides reliable measurement where space and weight are a concern. The corrosion resistant construction and compact design can handle the toughest of environments.

- Thermally compensated from 0 to 80C

- Weight: ~12 grams

- Total length of less than 1 inch

- Operating temperature range -60 °C to 130 °C

- Static accuracy to 0.5% FSO

- Pressure Range: from 0-100 to 0-5000 PSI

Temperatures Transducers

Model 7800 Aerospace Grade Temperature Transducer: Reliable temperature measurement while withstanding the harsh conditions associated with space exploration. Used for on-board space flight or military vehicle applications.

- High accuracy upto 1% FSO

- -100 °F to +250 °F (-73 °C to +120 °C)

- Hydrogen and LOX compatibility

- 100 Ω platinum RTD

Model 7880 Dual Pressure Temperature Transducer: Reliable measurements while withstanding the harsh conditions associated with space exploration. Used for on-board space flight or military vehicle applications

- Dual pressure and temperature outputs

- -65 °F to +250 °F (-59 °C to +120 °C) operating temperature

- Hydrogen and LOX compatible designs

- Designed for MIL-STD-810

Model 7710 Cryogenic Temperature Transducer: high-reliability low-temperature measurements Remotely mounted electronics provide a high-level signal output as well as choice of RS232, RS485 or CAN protocol, for improved cryogenic measurement accuracy and higher resolution.

- Cryogenic service down to -320 °F (-196 °C

- Accuracy of ±1% FSO

- Hydrogen and LOX compatibility

Flow Meters

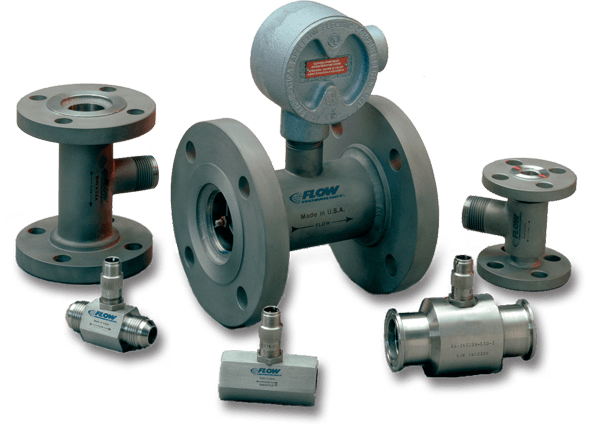

Turbine Flowmeters

FT Series: Proven flow measurement technology to provide accurate and reliable digital output for liquid and gas flow. Applications- Automotive, aerospace test stands, subsea control systems, feedback and control systems on aeroderivative turbine generators, Industrial.

- Liquid Flow Rates: 0.03 to 1,500 GPM (0.11 to 5,677 LPM)

- Gas Flow Rates: 0.09 to 1,500 ACFM (2.55 to 42,480 ALPM)

- Accuracy: ±0.25%

- Repeatability: ±0.05% (liquid) and ±0.1% (gas) of reading.

HS Series: “High shock” turbine flowmeters are specifically designed to withstand pressure spikes that create hydraulic shock waves in fluids when actuators or rams are activated. Ruggedized housing and reinforced rotor to eliminate protential damage from fluid shock.

- Flow Rates: 0.03 to 450 GPM (0.1 to 1,700 LPM)

- Accuracy: ±0.25%

- Repeatability: ±0.05% of reading

- High line pressures and hydraulic shock load applications

FTO Series: Omniflo® turbine flowmeters utilize a low frictional drag bearing in a tangential design allowing the measurement of very low flow rates in either liquid or gas. These high resolution, low flow sensing instruments are capable of measuring low flow rates.

- Liquid Flow Rates: 0.001 to 2.0 GPM (3.78 to 7,570 mLPM)

- Gas Flow Rates: 0.0015 to 0.3 ACFM (2.55 to 510 ALPH)

- Accuracy: ±0.25%

- Repeatability: ±0.1% of reading

Positive Displacement Flow Meters

DC-I SERIES: Ideal for a wide variety of liquid flow applications. These applications include, but are not limited to, paints, resins, petrochemicals, lubricants, fuels, polyurethanes and adhesives.

- Line Size: 1/8 to 2 inch

- Viscosities Range: Up to 1,000,000 cP+

- Repeatability: ±0.05% of rate

- Operating Pressure: Up to 1000 psig

HP-I SERIES: Ideal for liquid flow applications where process pressure is above 1,000 psig. Applications may include hydraulics, polymers, polyurethanes, plastics, and adhesives.

- Line Size: 1/8 to 1 inch

- Repeatability: ±0.05% of rate

- Operating Pressure: Up to 3000 psig

- Viscosity Range: Up to 1,000,000 cP+

TRICKLEMETER: Ideal for measuring very low flows of low to high viscosity liquids. Its positive displacement design provides rugged, reliable operation for a variety of industrial applications.

- Designed for low flow rates, 0.005 to 0.5 GPM

- Line Size: 3/8 inch

- Repeatability: ±0.05% of rate

- Pressure: Up to 1000 psig

Clamp-on ultrasonic Flowmeters

SLF-500 Meter: Accurate, reliable and cost-effective clamp-on ultrasonic instrument capable of measuring bidirectional flow through metal, plastic and even lined pipes without altering the piping.

- Piping from 1 to 12 inches

- Accuracy: +/- 2% of reading

- Temperature range: -4 to 140 F

- Repeatability: +/-0.2%

SLF-200 Meter: Accurate, reliable and cost-effective clamp-on ultrasonic instrument capable of measuring flow through metal, plastic and various other pipe material without altering the piping.

- Piping from 1 to 12 inches

- Accuracy: +/- 2% of reading

- Temperature range: -4 to 140 F

- Repeatability: +/-0.2%

Model SLF-100 Meter: Accurate, reliable and cost-effective clamp-on ultrasonic instrument capable of measuring low flow rates through small diameter PFA tube without altering the piping.

- Specifically for 3/8, 1/2 and 3/4 inch PFA tubing

- Accuracy: +/- 2% of reading

- Temperature range: 50 to 140 F

- Repeatability: +/-0.2%

In-Line Ultrasonic Flow Meters

QCT Series: Small footprint, lightweight device is ideal for low viscosity liquid applications including water, water-based products, oils, and its all plastic construction makes it the meter of choice for many corrosive fluids.

- For Piping 1/8″ to 1″

- Accuracy: +/- 0.5% of reading

- Repeatability: +/- 0.2% over 10:1 calibration range

- Temp range: -10° to 80° C

QEM Series: Small footprint, lightweight device is ideal for low viscosity liquid applications including water, water-based products, oils, and its plastic and stainless steel construction makes it the meter of choice for many corrosive fluids.

- Flow rates to 65 gpm, 3/4″, 1″, 1-1/4″

- Accuracy: Calibrated, +/-0.25% of reading

- Temperature Range: -10° to 80° C

- Repeatability: +/-0.10%

QLF Series: Small footprint, lightweight device is ideal for low viscosity liquid applications including water, water-based products, oils, and its all plastic construction makes it the meter of choice for many corrosive fluids.

- Minimum flow 0.001 gpm

- High accuracy

- Low pressure drop

- 3500:1 turndown

- No moving parts

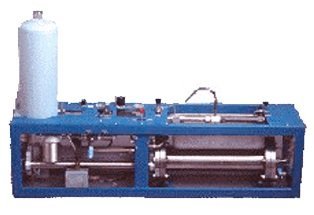

Flowmeter Calibrators

Primary Standard Liquid Calibration Systems – MICROTRAK/OMNITRAK: Computer–assisted liquid flowmeter calibration systems provide performance, reliability and economical benefits of ownership. Exceptional accuracy and stability are achieved from a precisely honed, chrome–plated stainless steel cylinder used to displace the fluid used for calibration.

- Calibrates ALL flowmeter technologies including:Coriolis, Turbine, Orifice, PD, Variable Area,Venturi, and Vortex

- Flow range of 0.001 to 400 GPM (0.004 to 1500 LPM)

- ± 0.05% uncertainty of volumetric flow rate measurement (95% C.L.) typical

- Flowmeter pulse, magnetic pickoff, RF pickoff and manual inputs std.

- Directly Traceable to NIST via Water draw validation

Primary Standard Gas Calibration Systems – AUTOBELL: Accurately measure a displaced volume of gas at a constant pressure. Interface electronics are provided to measure displaced volume and the time over which the volume is displaced so that a precise flow rate can be determined. To calibrate a gas flow meter using the Autobell®, the flow meter must be installed upstream of the bell so that all gas flowing through it is captured by the calibrator

- Calibrates all principal types of flowmeters: turbine, variable area and thermal

- Flow range of 0.1 to 125 ACFM (2.83 to 3540 ALPM)

- +/- 0.2% uncertainty of volumetric flow rate measurement (95% C.L.) typical

- Interface using menu driven CalWare software

- Directly traceable to the National Institute of Standards and Technology (NIST)

- Automatic data acquisition through PC and interface.

- Displays, prints and analyzes data in desired units of measure

Signal Conditioning