Instrumentation & Control

Automatism

Automate model: Study of a controlled systemWith two controllers on the networt Can be decomposed into two subsystems

- Differential pressure sensor.

- 6 float level sensor.

- The 4-20mA signals available on wiring terminals

Automated pumping station: Study of a water control distribution network Management of contact AON of buttons, pumps of controls and indicators

- Submersible pump with safety float.

- 2 level sensor low flow.Light indicators.

- Aluminum profile framework 45 x 45mm

Permutation of pumps: Study of a simple automated process, filling of a tank and drainage, compact system that works in closed circuit

- 50L, in PVC, with transparent face, syphon darning valve.

- Electrovalves.

- Six level detectors.

Complex control loops

Variable process control trainer: Study and adjust a number of simple control and cascade loops Temperature control ,Level control ,Flow control, Pressure control

- Temperature probes Pt100Ω.

- Float flowmeter.

- Electromagnetic flowmeter transmitter.

- Relative pressure transmitter.

Cascade control: Study of Flow and level simple control loops and Flow/level cascade loop commissioning

- Electromagnetic flow transmitter.

- Relative pressure transmitter

- The 4-20mA signals available on wiring terminals.

Conductivity control: Study and setting a loop conductivity, by share on a peristaltic pump

- Conduct meter probe. Flowmeter.

- Configurable electronic PID control.

- The 4-20mA signals available on wiring terminals.

pH control: Study and setting pH control loop , pH transmitter study and calibrationPID controller usingOpen loop Closed loop

- PID configurable controller.

- Electronic pH transmitter with local display, signal 4-20mA

- Adjustable overflow tube.

Level control integrator: Study a level control integrator loop, level / flow rate cascade loop

- 50L feeding tank

- Centrifugal pump

- Flowrate transmitter

Split range control water: Study of Water flow split range control SS centrifugal pump with adjustable speed variator, by-pass .Control valve with numerical electropneumatical positioner, high flow.

- Electromagnetic flow transmitter.

- The 4-20mA signals available on wiring terminals.

- Compressed air circuit.

Single control loops

Control of the water flow: Comprehension of flowrate measurement using,Floating ball flowmeter,Turbine flowmeter with rotation detector,Paddle wheel flowmeter

- Flow rate measurement by orifice

- Differential electronic pressure transmitter local display.

- The 4-20mA signals available on wiring terminals

Level control: Study and adjust a level control loop Industrial actuators and sensors setting and Use a PID controller,Open loop and Closed loop

- Cylindrical PVC transparent graduated tank.

- Relative pressure transmitter : 0 to 60 mbar for hydrostatic level measurement.

- PID configurable controller.

Pressure control: Study and adjust a pressure control loop Industrial actuators and sensors setting and Use a PID controller,Open loop and Closed loop study

- Manometers.

- Electronic relative pressure transmitter, scale 0 to 2 bar.

- PID configurable controller.

Control valve : Study the operation of an industrial pneumatic control valve With or without positioned Water reducing valve with control pressure gauge

- Float flowmeter.

- Differential electronic pressure transmitter with local display.

- The 4-20mA signals available on wiring terminals

Water flow control: Study and adjust a flow control loop Industrial actuators and sensors setting and Use a PID controller ,Open loop and Closed loop study

- Electronic differential pressure transmitter 0 – 250 mbar.

- Float flowmeter 15 – 150 L/h.

- PID configurable controller.

Sensors

Air temperature sensors: Temperature sensors different technologies study and comparison and also study a temperature control loop

- Differential pressure transmitter.

- Neutral gas dilation thermometer

- PID configurable controller.

Level sensor: Study of different methods of level measurement ,Ultrasound, Capacitive ,Hydrostatic immersion

- Capacitive sensor and transmitter, 4-20 mA.

- Ultrasonic sensor and 4-20mA transmitter, local indication.

- Hydrostatic sensor immersion and 4-20 mA transmitter.

Pressure sensors: Understanding of various pressures measured,Absolute pressure,Relative pressure,Differential pressure

- Differential pressure transmitter.

- Relative pressure transmitter 4-20mA.

- Absolute pressure transmitter 4-20mA.

- Pressure gauge.

Data Acquisition System

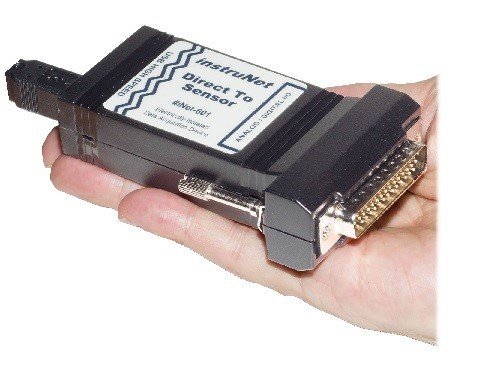

i60x Standalone Miniature USB Data Acquisition: The USB Data Acquisition is the smallest and most accurate electrically-isolated 8channel direct-to-sensor data acquisition system in the world.

- 16se/8di Voltage Inputs

- Connect Directly To Sensors: Voltage, Thermocouple, Thermistor, RTD, Load Cell, Strain Gage, Potentiometer, Current, Resistance

- 24-bit A/D with ±20mV through ±10V ranges

- 4x Digital I/O (4mA sink/source, 0 to 3.3V)

i330 OPTICAL ISOLATION: The optical Isolator provides 1000 Volts of optical isolation at one point within an instruNet network. This is often used to eliminate ground loops between the computer and items under test, and to reduce noise that is transmitted from the computer to sensors.

- Multiple Model 330’s can be placed in one network

- Optical Isolator between i2x0 controller and i4xx/i100. Requires Additional power supply

i4xx Card Cage System: The i4xx cards slide into an instruNet card cage that is 4, 8, 12 or 16 slots wide. Cards are held into position with jackscrews that are tightened with a slotted screw driver.

- Solid aluminium construction

- The i400 is 15 x 11 x 14 cm in size (6 x 4.5 x 5.6 inches, d/w/h)

- Each i400 supports up to four i4xx cards

- Multiple i400’s can be bolted together by the end user, side-by-side, to create an 8, 12, or 16 slot system

i555 STARTER CARD CAGE SYSTEM: instruNet i555 is the highest-accuracy data acquisition system for performing low-level measurements (e.g. ±100mV). The instruNet card cage does not contain a noisy processor, which makes it easier to do accurate low level measurements. Low level measurements are required by many sensors, such as thermocouples, strain gages and load cells; which respectively measure temperature, bending and weight.

- I555 System, includes i240, i400, i410, i430, i312.8, i510

- Includes Free instruNet World strip chart recorder software; or purchase powerful PLUS version.

- USB 2.0 High Speed Data Acquisition Hardware for Windows ≥ Xp Sp3 (Xp/Vs/7/8/10)

- Easily expand via 2 free slots in 4 slot i4xx Card Cage

i4xx Data Acquisition Cards: The i4xx card connects an i4xx Card Cage to a Windows computer via an instruNet i240 USB, i200 PCI or i230 PCMCIA controller card. The i410 plugs into the left-most slot (slot #1) of an i4xx Card cage.

- Two Db25 connectors allow daisy-chaining multiple i4xx Card Cage and i100 devices to one i2x0 controller card.

- Front panel red power light shows presence of 5V, 12V, and -12V power.

- i4xx series have below variant.

| #iNet-410 | Interface between i2x0 ctlr & i4xx card cage, includes 3m cable |

| #iNet-420 | 20se/10di voltage input, multiplexor, 4 digital i/o |

| #iNet-423 | 6di voltage input, amplifier, filter, 4 digital i/o |

| #iNet-430 | 16bit A/D, 16se/8di voltage input, mux, 4 voltage out, 4 digital i/o |

| #iNet-460 | 28 digital i/o channels |

i2x0 Controller: The i2x0 USB instruNet Controller is used to connect a computer to an instruNet network via the USB 2.0 High Speed bus (480M bits/sec). An instruNet network consists of i4xx Card Cages and i100 boxes which are daisy-chained together.

- Each Controller card manages up to eight i100/i4xx Devices and includes an instruNet Terminator and instruNet software.

- instruNet i2x0 controller series have below variants.

| #iNet-240 | USB Device for Windows ≥ XP Sp3, without iW+. Requires computer with 1 free USB ≥ 2.0 High Speed port |

| #iNet-200 | PCI-Bus Card for Windows ≥ Xp, without iW+. Requires computer with 1 free PCI slot |

| #iNet-230 | PCMCIA-Bus Card for Windows ≥ Xp, without iW+. Requires computer with free PCMCIA slot & i312.8 supply |

| #iNet-240P | Same as iNet-240, yet includes PLUS (iW+) software |

i100 DATA ACQUISITION BOXES: Each i100 box provides 16se/8di Analogue Inputs, 8 Analogue Outputs, and 8 Digital I/O lines; and includes Db25 Male to Female 3 meter Cable. The “HC” model is commended for strain gages, thermistors, RTD’s, Load Cells, and Pots.

| #iNet-100 | instruNet External A/D Box with 3m cable |

| #iNet-100B | Same as above, yet with additional 16 BNC Connectors |

| #iNet-100HC | Same as iNet-100, yet with 15mA/.01uF voltage output channels |