Refrigeration & Air Conditioning

Air Conditioning laboratory Unit: A complete, upgradeable, instrumented air conditioning laboratory unit mounted on a steel frame and castor wheels. upgrades may be added at any stage in the unit’s long life to spread the investment costs. available upgrades options: 1. re-circulation, 2. computer linking (with software), 3. pid control and environmental chamber.

- high accuracy wet and dry bulb sensors before and after each process to determine air condition.

- Energy and mass balances across each process of heating cooling and humidity change.

Refrigeration Cycle Demonstration Unit: : A bench mounted vapour compression refrigeration cycle demonstration unit using a hermetic compressor. the water cooled flooded glass condenser and evaporator allows both evaporation and condensation to be observed and understood. the unit operates on low-pressure non-toxic ozone friendly refrigerant. internal electrical and mechanical safety devices allow for unsupervised operation by students.

- panel: high quality grp.

- condenser: vertical, thick walled high strength glass cylinder.

- evaporator: flooded type, similar to condenser.

Vortex Tube Refrigerator: The vortex tube refrigeration unit uses a compressed gas (usually air) divided into two streams at a lower pressure. one of these streams is about 50k colder, and the other is about 50k hotter than the compressed gas supplied. it is an unusual method for producing cooling air.

- demonstration of the ability to produce hot and cold air from a device with no moving parts.

- safe and suitable for unsupervised student operation

- does not involve any chemical refrigerants

- responds rapidly to control changes

Mechanical Heat Pump: The mechanical heat pump has been designed to allow students to obtain an overall understanding and appreciation of the performance and characteristics of a heat pump working on the vapour compression cycle and having an electrically driven compressor, and is suitable for all course levels, from vocational to undergraduate.

- stabilises in minutes allowing many tests to be conducted in a typical laboratory period.

- allows a complete refrigerant pressure-enthalpy cycle diagram to be drawn at all operating conditions.

- operates on cfc free r134a refrigerant.

- allows a complete energy balance to be performed between electrical input and thermal input/output.

Air and Water Heat Pump: The vapour compression cycle is the most common form of refrigeration, transferring heat from the area being cooled to a higher temperature region. heat pumps use this effect to recover heat at a useful temperature for heating or some other process by upgrading low grade ‘free’ heat e.g. from ambient air or water.

- vapour compression heat pump that allows performance investigation from both air and water sources.

- rapid stabilisation enables detailed investigation in a typical laboratory period

- permits refrigerant pressure-enthalpy cycle diagrams to be drawn at all operating conditions

- optional computerised data acquisition upgrade

Vapour Jet Refrigerator/Heat Pump: The unit may be regarded as a combined heat engine and a refrigerator/heat pump. the system powering the refrigerator/heat pump works on the well-known rankine cycle.

- enables demonstration and investigation of the combined rankine and vapour compression cycle

- evaporation and condensation may clearly be seen through glass cylinders

- as a heat pump, the unit shows approximately the same primary energy ratio as a work-driven heat pump

Visual Refrigeration Training Unit: This unit is designed to demonstrate the basic principles of heat transfer, the vapour compression refrigeration cycle and the function and application of different flow controls.

- shows clearly the basic principles of the vapour compression refrigeration cycle

- introduces the concepts of change of state, saturated liquid, saturated vapour and superheated vapour.

- optional student tool kit, test and service equipment

Reverse Cycle Refrigeration And Air Conditioning Unit: This unit allows students to explore a more sophisticated refrigeration system incorporating reverse cycle operation, air cooled and water cooled condensers, forced air and static evaporators and dual temperature operation.

- air cooled and water cooled condenser

- forced air and static evaporator with dual temperature operation

- optional student tool kit, test and service equipment

- demonstrates common faults and effects on the system

Water Chiller Trainer: This unit allows students to safely explore the parameters affecting evaporating pressure without danger to the operator or equipment.

- fully operational water chiller with cooling load

- evaporator pressure regulator to demonstrate non-freeze cooling

- optional data acquisition available.

- optional student tool kit, test and service equipment

Internal Combustion Engines

Combusion Laboratory Unit – Gas and Oil Burner: Enables students to study many aspects of combustion theory and burner operation using the optional gas and oil burners. Domestic heating simulation can also be demonstrated via the in-built water temperature control.

- Chamber: Stainless steel with glass windows

- Fuel and air adjustment

- Flue Gas Analysis

Flame Propagation and Stability Unit : Allows investigation of the relationship between flame speed and air – fuel ratio for a variety of slow burning gaseous fuels. gaseous fuels (e.g. Propane, Butane, Methane LPG)

- Flame Lift Off&Flame Light Back

- flame stability

- horizontal and vertical flame movement

Bomb Calorimeter: Allows measurement of the calorific value of liquid and solid fuels by a fundamental rate of rise method

Internal Combustion Engine Test Stand- GASOLINE and DIESEL: the investigation of torque-speed, power-speed, specific fuel consumption, thermal and mechanical efficiency over a wide range of conditions on both petrol and diesel* engines

- Regenerative Engine Test Bed

- Four Stroke Gasoline & Diesel Engine

- High quality efficient engine

Diesel Engine Lab: Diesel Dynatronix™ is a portable diesel engine performance analysis system comprised of a two-cylinder industrial diesel engine driving an air-cooled dynamometer. It enables the control and performance testing of a modern industrial diesel power plant.

- Lamborghini/Kohler KD-625-2 Engine

- Allen Bradley L18ERM Programmable Automation Controller

Automotive Air Conditioning Trainer: is designed to understand the operation, fault finding, maintenance and repair of automotive air conditioning systems.

- Electric Motor nominal 1500rpm with overload cut out.

- Air cooled condenser and fan with 12v dc motor

- Transformer to provide 12v automotive control circuit.

Minilab: MiniLab™ is a self-contained SR30 turbojet engine, offers exciting teaching opportunities in applied thermodynamics and jet propulsion. A DAQ system displays and records compressor inlet temperature and pressure, turbine inlet temperature and pressure, turbine exit temperature and pressure, thrust and fuel flow.

- Maximum RPM: 87,000

- Maximum Thrust: 40 lbf (178 N)

- Approved Fuels: Jet A, A-1, B; JP-4, 5, 8; Kerosene, Diesel, Fuel Oil #1 or #2

Turbogen: The primary component of TurboGen™ is a self-contained turbo shaft engine. A complete micro turbine genset to consist of an engine/generator combination designed and manufactured specifically for engineering education. The engines mechanically-free power turbine drives an electric generator.

- Adjustable Rotor Excitation

- Maximum Thrust: 40 lbf (178 N)

- Generator Maximum Power: 2541 Watts

- GeneratorMaximum RPM: 10,000

Heat and Mass Transfer

Heat Exchanger Service Unit: A bench mounted ,Optional heat exchangers: Concentric Tube ,Plate ,Shell & Tube,Jacketed Vessel with Coil and Stirrer, Extended Concentric Tube ,Extended Plate ,Water/Water Turbulent Flow ,Coiled Concentric Tube ,Recycle Loops Film and Dropwise Condensation Water to Air.

- Re-circulating hot water circuit

- Responds rapidly to control changes

- Re-circulating hot water circuit

Heat Transfer Service Unit: Bench Top 15 Fundamental Heat Transfer Experiments may be used on the Heat Transfer Service Unit Convection, Conduction, Radiation, Gas Laws ,Steady State and Transient Heat Transfer .For detailed descriptions and experimental capabilities refer to data sheets for each optional unit.

- ONE unit to connect with 15 options

- Responds Rapidly to Control Changes

- Computerised Data Acquisition Upgrade.

Cross Flow Heat Exchanger: Allows Investigation Of Plain And Finned Cross Flow Heat Exchangers. Heat Pipe , Expandable Free & Forced Convection Heat Transfer Investigation, Local Heat Transfer Coefficient around a cylinder. More Experimental capabilities 8 Optional available refer to data sheets.

Boyle’s Law Demonstrator: Study of Boyle’s Law pv = Constant for air and other safe gases. Investigation of the characteristic equation of a gas pV = mRT at ambient temperature.

- Thermodynamics

- Glass cylinder volume: 1 litre.

- Compressor: 500W.

Flow Boiling Demonstration Unit: Demonstration of a heating process accompanied by vapour formation within a tube, two phase flow with increasing vapour content, effect of air in condensers. Slugging ,Annular flow , Droplet

- Circulation promoted by natural convection

- Convective heat transfer to sub-cooled liquid

- Nucleation in sub-cooled and saturated liquid

Boiling Heat Transfer Unit: Allows safe investigation into the normally dangerous condition of film boiling heat flux and surface heat transfer coefficient at constant temperature Ozone-friendly, low pressure, non-toxic working fluid

Bench Top Cooling Tower: Demonstrates all processes found in a full scale forced draught cooling tower Rapid stabilisation allows experimental work to commence immediately upon switching on.

- water flow pattern and distribution

- digital temperature indicator

- External Loads of up to 1.5 kW

Humidity Measurement Bench: allows students to investigate most of the wide variety of methods to measure the humidity of air.fundamental for the study of air conditioning and evaporative cooling methods.

- Humidity Measurement Device

- Effects Of Air Velocity On Wet Bulb

- Optional Electronic Transducer

Dew Point Hygrometer: Measurement of ambient dew point using the chilled mirror method Measurement of dew point of air sampled from an air duct or other source.

- Directly measures Ambient Dew Point

- Allows sampling of air from remote locations such as air ducts

- Rapid operation and reversibility

Film and Dropwide Condensation Unit: Measurement of heat flux and surface heat transfer coefficient in both filmwise and dropwise condensation at pressures up to atmospheric. filmwise and dropwise condensation, and of nucleate boiling.

- effect of air in condensers.

- steam generator and air extraction

- Daltons Law.

Fluidisation and Fluid Bed Heat Transfer: Observation of the behaviour in fluidised bed of a wide range of granular materials, from onset of fluidization, air flow and pressure drop through avariety of granular materials.

- Granula Material: Fused Alumina

- Digital Thermometer,Digital Wattmeter

- Bed Chamber: Ø105 x 220mm

Steam of Water Heat Exchanger: Visual demonstration of filmwise condensation nucleate boiling. effect of coolant flow velocity and the number of tube passes on pressure drop.

- Digital Thermometer: Resolution 0.1°C.

- Pressure Gauge: Range: – 100 to +100 kN/m2.

- Differential Pressure transducer and Display.

Temperature Measurement Methods and Calibration Unit: Allows students to thoroughly examine a large variety of temperature measurement devices, how errors can be introduced and avoided, methods of calibration and the structure of the International Temperature Scale (ITS-90)

- Platinum resistance temperature indicator

- Thermistor temperature indicator

- Thermocouple

Concentric Tube Heat Exchanger: Investigate Logarithmic Mean Temperature difference, Overall Heat Transfer Coefficient and the Nusselt, Reynolds, Prandtl Relationship.Stabilises in minutes and allows rapid data collection.

- Heat Exchanger: Concentric tube

- Water Heater: 3kW with electronic control

- Digital Thermometer: 0.1ºC resolution

Theory of Machines

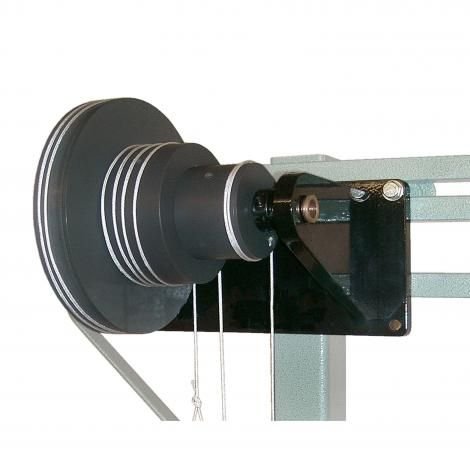

Wheel and Differential Axle Apparatus: Investigation of the mechanics of simple wheel and differential axle. variation with load of effort, efficiency, Limiting efficiency of the machine.

- Velocity Ratio: 10.5 : 1

- Relationship between Load and Effort

- Locking Mechanism

Gear Tooth Form Apparatus: Experimental determination of shape and construction of an involutes curve, Gear Form, Ratios, Modules ,Trains and Rotational Direction.

- Theory and terminology

- Pitch Circle Diameter (PCD)

- Gear Geometry

Cam and Follower Apparatus: To derive the velocity and acceleration diagrams, and determine the maximum acceleration of the follower and effect of different cams.

Crank and Connecting Rod Apparatus: To determine the relationship between crank angle and stroke,effect of changing the crank radius and connecting rod length.

- Linear Motion to Rotation

- Crank, piston, flywheel

- Engraved protractors

Castor, Camber and King Pin Inclination: Bench mounted apparatus designed around the front steering arrangement of a vehicle. Shows precisely the set up of castor, camber and king pin inclination.

- King Pin inclination

- Toe in, toe out

- dynamic stability of the wheel

Gear Train Apparatus: Compact apparatus for investigating transmission ratios on single stage, two stage and planetary spur gear drives.

- Transmission ratios for single, double stage

- Planetary spur gear drives

- Durable plastic gears

Disc Brake Apparatus: Frame or wall mounted apparatus to investigate the relationship between the normal force acting on the brake pads, the effective radius of the brake pads and the braking torque

- Braking Force, Torque

- Friction coefficient

- Three pad radii

Static & Dynamic Balancing Apparatus: A bench top unit to demonstrate the fundamentals of static and dynamic balancing. Allows independent analysis of static and dynamic balancing.

- Static& Dynamic balancing

- Non-coplanar masses

- Speed controlled

Governor Apparatus: Bench top unit to demonstrate the principle of operation of Porter, Propel and Hartwell centrifugal force governors.To observe the lift off speed and affect of varying sleeve weight.

Gear Assembly Unit Combined Drives: Introduction to gear trains, transmissions, ratios, velocities, spur gears, drive belts, pulleys, chains, tensioners, worm and wheel, bevel gears, rack and pinions, compound drives

- Floor or Bench top apparatus

- Manual driving of system

- Smooth, quality frame

Single Epicyclical Gear Train: Experimentally obtain the torque ratios of gear trains, observe the angular velocity ratios of gear trains, efficiencies of gear trains.

- Input/output shafts

- Locking devices to stop rotation

- Epicyclic Gears

Governor Apparatus: Bench top unit to demonstrate the principle of operation of Porter, Propel and Hartwell centrifugal force governors.To observe the lift off speed and affect of varying sleeve weight.

Fluid Mechanics

Base Unit: The HB100 Hydraulics Bench is the main source of water supply/ flow for all the additional modules within the HB series including water storage tank.

- Closed system for re-use of water

- Storage tank capacity: 75 litres

- Centrifugal pump: 0.365kw

Free and Forced Vortices: Determination of the surface profile and radii of various size free and forced vortices. Determination of total head variation of a free and forced vortex.

- Bernoulli’s theorem

- Helmholtz’s Theorem

- Vector Analysis

Bernoulli’s Theorem Demonstrator: Bernoulli’s theorem concerns the conservation of mass and energy through a flowing system and the relationship between the flow velocity and pressure , Direct measurement of the static head distribution along a Venturi tube.

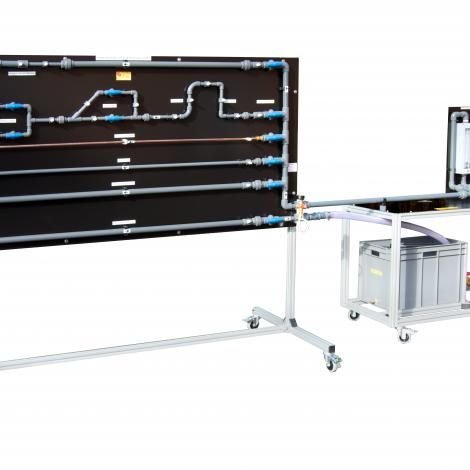

Pressure Losses in Bends and Fittings: Comprises different diameter, roughness and material pipes, along with long and short radius bends, parallel sections and constrictions. Reynolds number in a variety of pipe sizes pressure loss in a pipe using Bernoulli’s equation

- Laminar Boundary layer

- Friction Factor

- Fluid Velocity

Osborne Reynolds Apparatus: The Apparatus is used for the illustration and investigation of Laminar and Turbulent flow with the active flow visible to adye injection system

- Gate valve for flow rate control

- Dye injection system to aid visualisation

- Non corrosive materials

Pressure Measurement Bench: Allows Investigation of Different Methods of Pressure Measurement FIVE pressure methods Investigation of Pressures Above and Below Atmospheric Pressure. Fluid Density Effect

- Compound Bourdon Tube: -50 to +50 mBar

- Bourdon Tube: 0 to +60 mBar

- Linear manometer scale: 1mm resolution

Base Unit: The main unit consists of an instrumentation and control console that supplies a variable flow of compressed air to the range of optional modules.

- Nozzle Choking and Nozzle Efficiency

- Impulse Turbine& Reaction Turbine

- Digital Temperature Indicator: 0.1°C Resolution

Nozzle Performance Test Module: Visual demonstration of nozzle choking and effect of inlet and back pressure on mass flow rate through nozzles.

- Compressible Flow

- Supersonic Flow

- Fluid Acceleration

Nozzle Pressure Distribution Module: Visual demonstration of the phenomenon of choking ,pressure distribution in nozzles which are over and under expanding, effect of inlet pressure on mass flow rate.

Vortex Tube Refrigerator Module: Investigation of torque/speed and power/speed characteristics of a single stage reaction turbine. Application of the First Law of Thermodynamics.

- cooling or warming of protective clothing

- Chilling hot melt adhesives

- Cooling small plastic mouldings

Pipe Friction Module: Investigation of the pressure distribution and pipe friction along a pipe of varying cross section and bends, while passing a compressible flow of varying volume.

- Fluid Flow

- PressureDistribution

- Pipe Friction

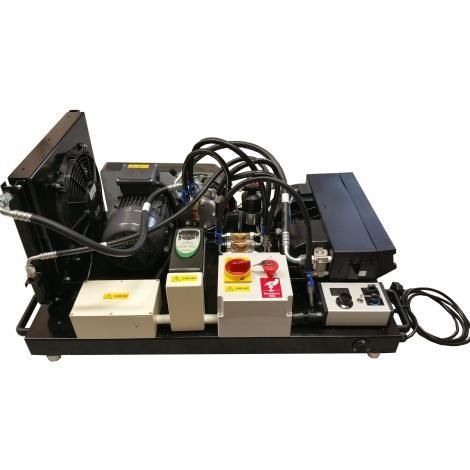

Process Automation Lab: FLUIDMechatronix™ allows students to study centrifugal pump performance curves, head/discharge curves, flow rate/torque correlations, witness impeller boundary layer conditions, and view cavitation

- Clear-View Centrifugal Pump with Easy Change-Out Impeller Profiles

- Clear-View Fluid Flow Circuitry Reveals All Flow and Cavitation Phenomena

- Fully Instrumented for Fluid Flow, Pressure, Temperature, Level, Power, and Efficiency Analysis

CNC Machines

C02 Laser Cutting & Engraving: SOur range of non-metal, mixed metal, laser cutting and engraving machines are built to standard specifications, giving customers easy to use and fully integrated capabilities to produce work of the highest standards.

- Auto-focus

- Integrated water cooling system for C02 laser source

- Windows software supporting DXF, JPEG, BMP, AI, Lightburn and more…

- Pre-configured & fully editable parameter library

Fibre Metal Cutting lasers: A range of metal cutting fibre laser systems built to Boxford specifications. Our high precision metal cutting fibre lasers are ideally suited to all kinds of training, prototyping and low to medium volume manufacturing applications.

- Auto-focus and one-click calibration

- Auto edge seek function for sheet location

- Integrated chiller based laser cooling system

- Windows compatible 2D drawing & nesting software supporting: DXF, DWG, AI and more…

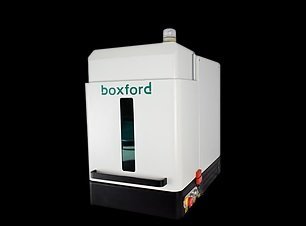

Fibre Marking Laser: Boxford fibre marking laser is a compact, fully enclosed and easy to use bench top machine, giving customers the ability to permanently mark a wide range of materials, whilst maintaining a safe working environment.

- Ability to mark a range of metals and some non-metals

- Ability to permanently mark logos, bar codes, QR codes and serial numbers

- Galvo laser head for rapid marking and engraving

- Motorised Z axis

Plasma Metal Cutting: The new Boxford Plasma Cutter is designed for your own exacting requirements. Our plasma cutting systems which are fully enclosed for optimal fume and debris management available with a variety of plasma sources from 40A to 80A.

- Automatic plate sensing

- Red dot pointer for plate location

- Automatic digital height control during cutting

- Intuitive software ideal for education and training

CNC Routers: The Boxford range of 3-axis CNC high performance routers are ideally suited to fulfil all levels of education and training requirements, as well as a host of design and commercial applications.

- Integrated touch sensitive control panel

- Interlocked solenoid guarding for safe usage

- Precision ground linear slides on all axes

- Latest motion control technology to produce a smooth & fast 3D environment

- USB interface

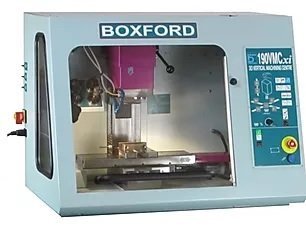

CNC Machining Centres: The Boxford range of 3-axis CNC Machining centres offer unrivalled performance and ease of use. Within a matter of minutes 2½D components incorporating pockets, slots, holes and text can be designed, simulated and manufactured in a variety of materials.

- Integrated touch sensitive control panel

- Interlocked solenoid guarding for safe usage

- Latest motion control technology to produce a smooth & fast 3D environment

- USB interface

CNC Lathe Turning Machines:: The Boxford range of CNC lathes offer users unrivalled performance and ease of use. Within a matter of minutes, components incorporating external and internal profiles, including screw threads, can be designed, simulated and manufactured to close tolerances in a variety of materials.

- Integrated touch sensitive control panel

- Interlocked solenoid guarding for safe usage

- Slant bed construction

- Pre-loaded anti-backlash ball screws on all axes

CNC Combination Machines: The innovative and unique Boxford range of combined lathes, machining centres and routers, offer users unrivalled performance and ease of use. Within a matter of minutes, both lathe components incorporating external and internal profiles can be designed, simulated and manufactured in a variety of materials.

- Integrated touch sensitive control panel

- Interlocked solenoid guarding for safe usage

- Pre-loaded anti-backlash ball screws on all axes

- Precision self-centring 3 jaw chuck

Manual machines: Boxford Lathes are renowned for their heavy duty construction and accuracy. Boxford drills can be fitted to a bench top or supplied floor standing. These are robust and reliable and ideally suited to tool room, general engineering workshop requirements and vocational training programmes.

- Robust construction and made from quality materials

- 3 phase or single phase power supply options

- Essential safety features including: telescopic chuck guard, push button starter

Soldamatic Welding Training System: Soldamatic IE is the first Welding Training Solution powered with Augmented Reality (AR) in the world. Augmented Training proposes a new educational paradigm that promotes intensive practice, it is a dynamic and flexible model, which allows instructors to easily manage different courses with numerous students, regardless of their level of knowledge and/or learning pace.

- Ability to simulate MIG, TIG and Arc Welding

- Ability to simulate full 360 degree welding on a variety of work pieces and angles

- Three difficulty levels to allow student progression

Gravograph C02 Laser Cutting & Engraving Machines: The Boxford supplied range of CO2 Laser Engraving and Cutting Systems offer industrial levels of build quality and accuracy in a totally integrated package. The ease of use, compatibility with multiple design software packages, together with the wide variety of material they can process, makes these systems the ideal choice for all educational and training requirements.

- Auto-focus

- Integrated air cooling system for RF laser tube source

- Windows software and drivers, including Laser Style CAD software

- 3 years parts and labour warranty